In the competitive manufacturing industry, implementing a robust CRM system is a game-changer. CRM for manufacturing companies offers a comprehensive solution to streamline operations, improve customer service, and drive efficiency.

By centralizing customer data, automating processes, and providing real-time insights, CRM empowers manufacturing companies to make informed decisions, respond promptly to customer inquiries, and foster long-lasting relationships.

Benefits of CRM for Manufacturing Companies

Implementing a CRM system in manufacturing companies offers a range of advantages that can significantly enhance operations and customer interactions. By providing a centralized platform for managing customer data, streamlining processes, and automating tasks, CRM systems can improve efficiency, increase productivity, and drive growth.

Streamlined Operations

CRM systems streamline manufacturing operations by centralizing customer information, automating workflows, and providing real-time visibility into the production process. This enables manufacturers to:

- Track customer orders and inventory levels in real-time.

- Automate order processing and fulfillment, reducing errors and delays.

- Improve communication and collaboration between departments, ensuring smooth coordination.

- Identify bottlenecks and inefficiencies in the production process, enabling timely corrective actions.

Improved Customer Service

CRM systems enhance customer service by providing a comprehensive view of customer interactions and preferences. This enables manufacturers to:

- Personalize customer interactions based on their history and preferences.

- Resolve customer inquiries and complaints promptly and effectively.

- Track customer feedback and identify areas for improvement.

- Build stronger customer relationships and increase customer loyalty.

Increased Efficiency

CRM systems automate many tasks that were previously performed manually, such as order processing, inventory management, and customer communication. This frees up manufacturing staff to focus on more value-added activities, such as product development and customer relationship management. As a result, manufacturers can:

- Reduce administrative costs and increase productivity.

- Improve production efficiency and reduce lead times.

- Free up staff time to focus on strategic initiatives.

- Gain a competitive advantage by leveraging technology to improve operations.

Challenges of Implementing CRM in Manufacturing

Implementing a CRM system in manufacturing companies can bring about significant benefits. However, it is not without its challenges. Manufacturing companies often face obstacles related to data integration, process alignment, and user adoption, which can hinder the successful implementation and utilization of CRM.

Data Integration

Manufacturing companies typically have complex data environments, with data stored in various systems such as ERP, MES, and PLM. Integrating these disparate systems with the CRM can be a daunting task, requiring extensive data mapping and transformation. Data inconsistencies and redundancy can also arise during integration, leading to challenges in maintaining data accuracy and integrity.

Process Alignment

Manufacturing processes are often highly structured and involve multiple stakeholders, including production, engineering, and sales. Aligning these processes with the CRM system can be challenging, especially when existing workflows and responsibilities need to be modified. Resistance to change and lack of clear process ownership can further complicate the alignment process.

User Adoption

Getting users to adopt a new CRM system can be a significant challenge in manufacturing environments. Resistance to change, lack of training, and perceived complexity of the system can all contribute to low user adoption rates. Ensuring that the CRM system is user-friendly, provides clear value, and aligns with the needs of the users is crucial for successful adoption.

Features of a CRM for Manufacturing

A CRM system designed for manufacturing companies should include specific features that cater to their unique requirements. These features enable manufacturers to manage customer relationships effectively throughout the manufacturing process, from lead generation to post-sales support.

Lead Management

Lead management is crucial for manufacturers to capture and qualify potential customers. A CRM system should provide tools for lead generation, lead qualification, and lead nurturing. This includes capturing leads from various sources, such as trade shows, website forms, and social media, and tracking their progress through the sales pipeline.

Opportunity Tracking

Once leads are qualified, manufacturers need to track opportunities and manage the sales process. A CRM system should provide features for opportunity management, including the ability to create and track opportunities, manage sales pipelines, and forecast revenue. This enables manufacturers to prioritize sales efforts and close deals efficiently.

Customer Support

Excellent customer support is essential for manufacturers to build strong relationships with customers. A CRM system should provide tools for managing customer support requests, tracking customer interactions, and resolving issues promptly. This includes features such as a knowledge base, ticketing system, and live chat support.

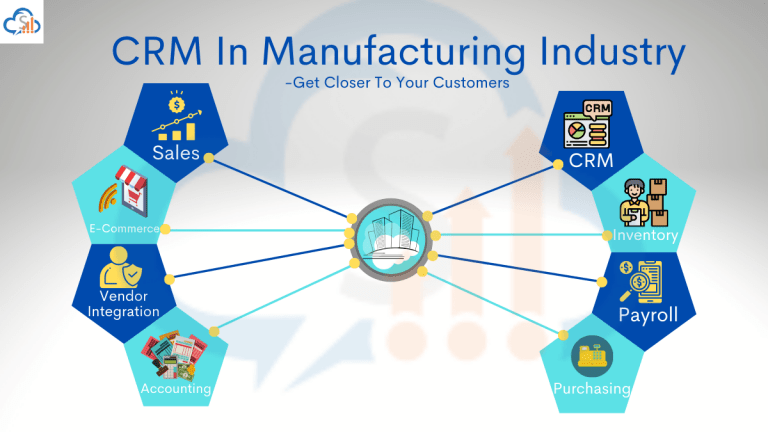

Integration of CRM with Other Systems

Integrating CRM with other business systems, such as Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES), is crucial for manufacturers. It enables a seamless flow of data and process automation, streamlining operations and enhancing efficiency.

Benefits of Integration

- Eliminates Data Silos:Integration breaks down data silos, allowing for real-time access to customer information across different systems.

- Improves Data Accuracy:Automated data transfer reduces errors and ensures consistency in customer data.

- Enhances Process Efficiency:Automated workflows eliminate manual processes, saving time and reducing the risk of errors.

- Provides a Holistic View:Integration provides a comprehensive view of customer interactions, enabling better decision-making.

Importance of Seamless Data Flow

Seamless data flow is essential for manufacturers to gain a complete understanding of customer needs and preferences. By integrating CRM with ERP and MES, manufacturers can track customer orders, production schedules, and delivery status in real-time. This enables them to respond quickly to customer inquiries, adjust production plans, and optimize inventory levels.

Benefits of Process Automation

Process automation streamlines manufacturing operations and reduces the need for manual intervention. For example, automated workflows can trigger order fulfillment, update inventory levels, and generate invoices based on customer interactions recorded in the CRM system. This automation reduces the risk of errors, improves efficiency, and frees up resources for more value-added activities.

Best Practices for CRM Implementation in Manufacturing

Effective CRM implementation in manufacturing requires a strategic approach and careful execution. Here’s a step-by-step guide to ensure successful adoption:

Stakeholder Involvement

Engage stakeholders from all relevant departments, including sales, marketing, operations, and customer service. Their input and buy-in are crucial for understanding business needs and ensuring alignment throughout the implementation process.

Data Management

Establish a robust data management strategy to ensure data accuracy, consistency, and accessibility. Implement data cleansing and standardization processes to eliminate duplicate or outdated information.

Change Management, Crm for manufacturing companies

Prepare for and manage organizational change effectively. Communicate the benefits of CRM to employees, provide training, and address resistance to adoption. Establish a change management plan to minimize disruptions and ensure a smooth transition.

Customization and Integration

Tailor the CRM system to specific manufacturing industry requirements. Integrate CRM with other systems such as ERP, supply chain management, and field service software to create a unified platform for managing customer interactions.

Continuous Improvement

Monitor CRM performance regularly and gather feedback from users. Identify areas for improvement and make adjustments to optimize the system’s functionality and effectiveness.

Case Studies of Successful CRM Implementations in Manufacturing

CRM systems have revolutionized the manufacturing industry, empowering companies to enhance customer relationships, streamline operations, and drive growth. Here are a few notable case studies that showcase the transformative impact of CRM:

Caterpillar

Caterpillar, a global leader in construction and mining equipment, implemented a CRM system to connect its disparate business units and improve customer service. The system enabled Caterpillar to:

- Consolidate customer data from multiple sources into a single, centralized repository

- Provide real-time visibility into customer interactions across all channels

- Improve communication and collaboration among sales, service, and marketing teams

- Personalize customer experiences based on their preferences and past interactions

John Deere

John Deere, a renowned manufacturer of agricultural equipment, deployed a CRM system to enhance its dealer relationships and optimize sales processes. The system helped John Deere:

- Manage dealer inventory and orders more efficiently

- Provide dealers with real-time access to product information and support

- Track dealer performance and identify areas for improvement

- Foster stronger relationships with dealers and increase customer satisfaction

Siemens

Siemens, a global technology conglomerate, implemented a CRM system to streamline its complex manufacturing processes and improve customer engagement. The system enabled Siemens to:

- Integrate data from multiple manufacturing plants and distribution channels

- Automate order processing and inventory management

- Provide customers with self-service portals and personalized product recommendations

- Reduce operational costs and improve overall efficiency

Future Trends in CRM for Manufacturing

The manufacturing industry is undergoing a rapid transformation, driven by emerging technologies and trends such as artificial intelligence (AI), the Internet of Things (IoT), and cloud computing. These advancements are having a profound impact on the way that manufacturers manage their customer relationships.

Here are some of the key trends that are shaping the future of CRM in manufacturing:

AI-Powered CRM

- AI is being used to automate many of the tasks that are traditionally performed by CRM systems, such as lead generation, lead qualification, and customer segmentation. This is freeing up CRM users to focus on more strategic tasks, such as building relationships with customers and developing new business opportunities.

- AI is also being used to provide manufacturers with real-time insights into their customer data. This information can be used to improve customer service, personalize marketing campaigns, and identify new opportunities for growth.

IoT-Enabled CRM

- The IoT is connecting more and more devices to the internet, including manufacturing equipment. This is providing manufacturers with a wealth of new data about their customers’ products and how they are being used.

- This data can be used to improve product design, develop new services, and create personalized marketing campaigns. It can also be used to identify potential problems with products before they occur, which can help to prevent costly recalls and repairs.

Cloud-Based CRM

- Cloud-based CRM systems are becoming increasingly popular in the manufacturing industry. These systems are hosted in the cloud, which means that manufacturers can access them from anywhere with an internet connection.

- Cloud-based CRM systems are also more scalable and affordable than on-premises CRM systems, making them a good option for manufacturers of all sizes.

These are just a few of the key trends that are shaping the future of CRM in manufacturing. As these trends continue to evolve, manufacturers will need to adapt their CRM strategies to take advantage of the new opportunities that they present.

Last Word

Embracing CRM in manufacturing not only optimizes operations but also lays the foundation for future growth. With its ability to integrate with other business systems, CRM provides a holistic view of the manufacturing process, enabling companies to adapt to changing market dynamics and customer demands.

Commonly Asked Questions

What are the key benefits of CRM for manufacturing companies?

CRM streamlines operations, improves customer service, increases efficiency, and provides real-time insights into the manufacturing process.

What are the challenges of implementing CRM in manufacturing?

Challenges include data integration, process alignment, user adoption, and ensuring compatibility with existing systems.

What are the essential features of a CRM for manufacturing companies?

Essential features include lead management, opportunity tracking, customer support, inventory management, and integration with ERP and MES systems.